How to measure the tolerance of ball bearings

Do you understand what bearing tolerances really mean? We've written this simple guide to explain the intricacies of the topic. To learn more about what "mean bore deviation" and "single bore deviation" refer to, keep reading.

Tolerances control the dimensional accuracy of a ball bearing

For exact tolerance limits, please view ou

ISO bearing tolerances start at P0 and then move upwards to precision grades P6, P5 and then P4. ISO tolerances are measured in thousandths of a millimetre (or microns). AFBMA (ABEC) bearing tolerances are often measured in ten-thousandths of an inch with grades Abec1, Abec3, Abec5 and Abec7.

Different Abec tolerance grades exist for instrument bearings (Abec1P, Abec3P, Abec5P, Abec7P) and thin-section bearings (Abec5T, Abec7T).

If the shaft and housing match the bearing tolerances and the bearing has tighter tolerances, it will enhance shaft/housing fit, reduce noise/vibration and lower starting/running torque.

Learn more about ball bearing noise and vibration.

Deviation

This determines how much the actual measurement is allowed to deviate from the nominal dimension, including bearing bore tolerance. The nominal dimension is what the manufacturer lists; for example, 6200 has a nominal bore of 10mm and 688 has a nominal bore of 8mm.

Deviation limits are crucial. Without international tolerance standards for bearings (ISO and AFBMA), manufacturers could vary. This might result in receiving a 688 bearing (8mm bore) with a 7mm bore that won’t fit. Deviation tolerances allow for smaller but not larger bores or outer diameter (OD).

Learn how to measure bore diameter.

Mean bore/OD deviation

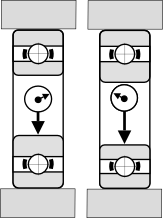

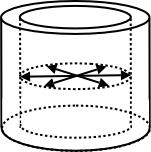

Single plane refers to bore diameter deviation, crucial for shaft-housing fit. Bearings aren’t perfectly round and when measured in microns, variations become clear.

If you take single measurements across different parts of a bearing's inner ring, you will get different readings so, what do you take as the bore size? This is where mean deviation helps. It involves measuring multiple points in one radial plane to find the average diameter of the ring’s bore or OD.

This drawing represents an inner bearing ring. The arrows represent various measurements taken across the bore in different directions to help discover the mean size.

However, a set of measurements in one radial plane is not enough. We need to check measurements in multiple radial planes to ensure the bore is within tolerance along its length.

Let’s say that a mean bore deviation tolerance for a P0 bearing is +0/-8 microns. This means that the mean bore can be between 7.992mm and 8.000mm. The same principle applies to the outer ring.

Width deviation

Width deviation, like bore and OD, needs to stay within tolerances. While width is less critical, tolerances are wider. A width deviation of +0/-120 for a 4mm wide bearing means it should be between 4mm and 3.880mm at any point.

Variation

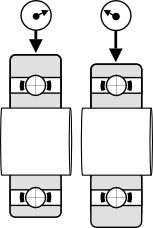

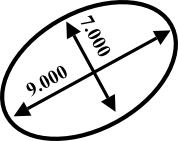

Variation tolerances ensure roundness. In this drawing of a badly out-of-round 688 inner ring, the largest measurement is 9.000mm and the smallest 7.000mm.

Calculating the mean bore size (9.000 + 7.000 ÷ 2) gives 8.000mm. It’s within mean bore deviation tolerance, but the bearing is still unusable. This shows that deviation and variation must complement each other.

Single bore/OD variation

In simple terms, bore/OD diameter variation occurs in a single radial plane In the diagram above, bore measurements range from 8.000mm and 7.996mm. The difference between the largest and smallest is 0.004mm, making the bore diameter variation in this single radial plane 0.004mm or 4 microns.

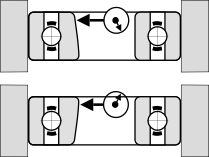

Mean bore/OD diameter variation

Thanks to mean bore/OD deviation and single bore/OD variation, we’re confident that our bearings are close enough to the correct size and are round enough. But what if there’s excessive taper on the bore or OD, as shown in the amplified diagram above? This is why we also have mean bore and OD variation limits.

To obtain mean bore or OD variation, we record the mean bore or OD in different radial planes and then check the difference between the largest and smallest. Assume that on the left here, the top set of measurements gives a mean bore size of 7.999mm, the middle is 7.997mm and the bottom is 7.994mm. Take the smallest away from the largest (7.999 - 7.994) and the result is 0.005mm. Our mean bore variation is 5 microns.

Width variation

Again, very straightforward. Let's assume, for a particular bearing, the permitted width variation is 15 microns. When checking the width of the inner or outer ring at various points, the largest measurement should not be more than 15 microns greater than the smallest measurement.

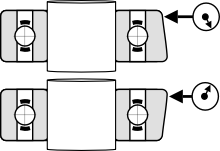

Radial runout

Radial runout of the assembled bearing inner/outer ring is yet another important aspect of bearing tolerances. If the mean deviation of both the inner and outer rings is okay and their roundness is within the allowed range, surely that's all we need to worry about?

Look at this diagram of a bearing inner ring. The bore deviation is okay and so is the bore variation, but look at how the ring width varies. Like everything else, ring width varies around the circumference and radial runout tolerances specify how much this can vary.

Inner ring runout

This is tested by measuring all points on a circle of the inner ring during one revolution, while the other ring stays still. Then subtract the smallest measurement from the largest. The radial runout figures given in the tolerance tables show the maximum variation allowed. The difference in ring thickness here is excessive to illustrate the point more clearly.

Outer ring runout

To check the outer ring runout, measure all points in a circle on the outer ring during one revolution. Then subtract the smallest measurement from the largest.

Face runout/bore

This tolerance ensures the bearing inner ring surface is close enough to a right angle with the inner ring face. Tolerance figures for face runout/bore are only given for bearings of P5 and P4 precision grades.

All points near the inner ring’s face bore are measured during one revolution, while the outer ring is still. The bearing is then turned over and the other side of the bore is checked. Take the largest measurement away from the smallest to get the face runout/bore tolerance.

Face runout/OD

This tolerance ensures the bearing outer ring surface is close enough to a right angle with the outer ring face. Tolerance figures for face runout/OD are given for P5 and P4 precision grades.

Measure all points near the outer ring's face in one circle during one revolution while keeping the inner ring still. The bearing is then turned over and the other side of the outer ring is checked. Take the largest measurement away from the smallest to get the face runout/OD bore tolerance.

Face runout and raceway runout assess the angle of the ring raceway surface compared to the ring face.

Still need assistance with measuring your ball bearing tolerances? Get in contact with our experienced team today by emailing sales@smbbearings.com or fill in the contact form.