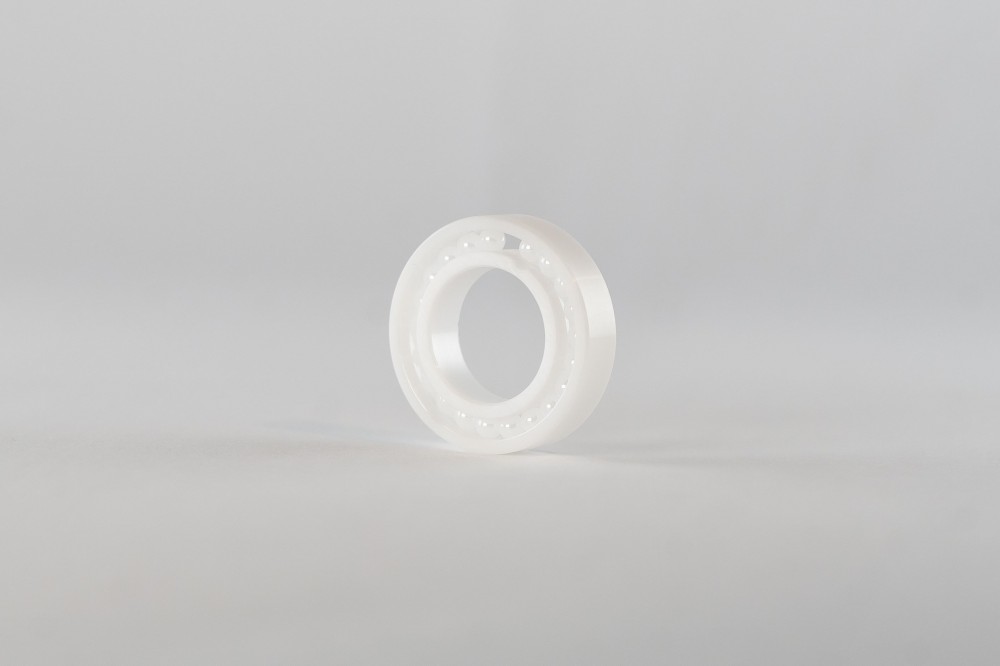

Ceramic ball bearing properties

Ceramic ball bearings play a crucial role in various industries due to their exceptional properties. The hardness of ceramic materials ensures superior resistance to wear and deformation, even under heavy loads and high-speed rotations. The hard surface of ceramic bearings reduces the likelihood of surface indentation and rolling contact fatigue, which leads to prolonged bearing life and enhanced reliability.

SMB Bearings supplies ceramic bearings in zirconium dioxide (ZrO2) for shaft sizes from 3mm up to 50mm. If you’re already confident in your selection, the product tables below will give you the necessary dimensions and technical drawings. Please also see our products variants below for Si3N4 ceramic bearing options.

However, if you’re asking yourself ‘What are the benefits of ceramic bearings?’ read on and discover our range.

Not be to be confused with hybrid ceramic bearings, full ceramic bearings have ceramic balls and rings, boasting harder than steel properties. Ceramic bearings, specifically full ceramic bearings made from ZrO2, offer numerous benefits that set them apart from standard steel bearings and hybrid ceramic bearings.

ZrO2 cage selection

The cage material used in ZrO2 bearings is crucial for their performance under specific conditions. The ZrO2 full ceramic bearings listed below are available with cages (or retainers) made from polyether ether ketone (PEEK) or polytetrafluoroethylene (PTFE). Bearings with bore sizes from 8mm upwards can also be fitted with 316 stainless steel cages.

In addition, we keep stock of full complement ZrO2 bearings. These bearings have no cage and extra balls. For full complement bearings, the load ratings are approximately 20 per cent higher, but the maximum speed is up to 70 per cent lower.

As for bearings with cages, PEEK cages are generally the preferred option available from SMB Bearings’ stock due to the polymer’s strength and durability. If an alternative cage material is required to cope with particular chemicals or temperature extremes beyond the range of PEEK, these can be produced to order.

Superior strength of ceramic bearings

One of the primary advantages of ceramic bearings is their hardness. ZrO2 is a tough ceramic material with very similar expansion properties to steel.

This is an advantage when considering shaft and housing fits for higher temperature applications. Although we usually refer to these bearings as ZrO2 bearings, they are actually made from ZrO2 stabilised with yttria, also known as yttrium oxide.

This air-stable, white solid substance gives the material greater strength and fracture resistance at room temperature. This is sometimes known as YSZ or YTZP.

Low coefficient of friction

Full ceramic ZrO2 bearings are hard, smooth and can be used without lubrication. They are commonly used in applications that need low turning resistance. Full ceramic bearings have a very low coefficient of friction compared to steel bearings or hybrid bearings. The coefficient of friction for unlubricated ZrO2 bearings, at ambient temperature in air with a light load, is approximately 0.0012.

Lightweight ceramic ball bearings

Another remarkable feature of ZrO2 bearings is their light weight, being approximately 30 per cent lighter than traditional steel bearings. This property contributes to their overall efficiency, especially in applications where weight reductions are critical such as aerospace.

Corrosion and water resistant

ZrO2 bearings are not magnetic or conductive, and they are highly corrosion resistant to most chemicals. They are also extremely water resistant which is why they are often used in marine applications — particularly where the equipment is fully submerged, or where 316 marine grade bearings will not cope with the load or speed. It’s important to note that if ZrO2 has prolonged contact with steam or hot water, there may be some weakening of the material over time.

Temperature tolerance

Full complement ZrO2 bearings, or those with a 316 stainless cage, can be used up to 600 degrees Celsius. Loads and speeds should be decreased as the temperature increases above ambient, particularly if the bearings are unlubricated and to a greater extent above 400 degrees Celsius.

Bearings with a PEEK cage are rated up to 250 degrees Celsius due to the lower maximum temperature of the cage material. It may be preferable to use a looser radial play at high temperatures. This especially applies if the inner ring temperature is likely to be greater than the outer ring temperature, as this will reduce the radial play of the bearing. That is why our ZrO2 bearings are supplied with a looser C3 radial play, as standard.

Although PEEK is very durable, it will become more brittle at low temperatures, so it is worth considering PTFE or 316 stainless steel cages for temperatures below -70 degrees Celsius. For a full overview of the pros and cons of ZrO2 bearings, see our ceramic bearing selection guide.

SMB Bearings' ceramic bearings stock

Most of our range of ZrO2 ceramic bearings are supplied from stock in the UK, shipping worldwide. We also supply full ceramic bearings from stock in silicon nitride. See the product variants below for the Si3N4 versions.

Click on INFO in the rows below to display technical drawings of the bearings with load and speed data. Please note that the maximum loads and speeds are used in theoretical life calculations.

To ensure reasonable bearing life, it is recommended to use bearings at significantly less than the maximum load and speed ratings. ZrO2 full ceramic bearings are best used at low speeds. For higher speeds or continuous rotation over long periods, they will perform better with Si3N4 balls.

The benefits of full ceramic ZrO2 bearings are substantial and make them an excellent choice for various industrial and high-performance applications.

Their hardness, low coefficient of friction, lightweight, and exceptional resistance to corrosion and chemicals provide advantages over traditional steel bearings. Whether in marine, aerospace, or high-temperature applications, ZrO2 bearings prove to be reliable, efficient and durable components. As technology and materials continue to advance, these innovative ceramic bearings will find even broader applications across various industries.

Not sure if ceramic bearings are right for you? Get in contact with our experienced team today by emailing sales@smbbearings.com.